Charles F.Peelle, a businessman and a fourth cousin to my great-grandfather William Johnson Peelle, got involved with the local safety gate company. When the owner sold out, Charles and his business partner purchased the company. Charles would file for the company’s first patent. This led to a family business that would exist across three centuries.

Who was Charles?

Who was Charles?

Charles F. Peelle was born to Henry and Mary (Morris) Peelle in 1857 at their home northeast of Cambridge City, Indiana, which was twenty miles west of Richmond. He was one of twelve or thirteen children (a source says there were 13, but I have only found 12).

The large family belonged to the Society of Friends. They were very active within the organization and at least a portion of the family, including Charles, continued throughout their adulthood. Charles belonged to the South Eighth Street Friends Church and was clerk of the Richmond Preparative Meeting of Orthodox Friends.

Charles was a business man. His primary business at his office at 901 Main St. was selling real estate and insurance. Additionally, he became involved in various businesses in the area. For example, he was one of the directors of the Diamond Roller-Skate Company, which had $100,000 in capital stock in 1884. He would not have yet been 30 years of age.

Charles was also active in the community in other ways and was said to be a “hardworking, energetic, and upright man.”

Safety Gates

John G. Zeller, a member of a prominent local family, started a business in 1880 to manufacture safety gates. These gates enclosed elevators and pre-dated elevator doors. He received a patent on his design and ran the business until 1890 when he accepted a position at the American Biscuit Company. As such, he sold his safety gate business at 914 Main St. to Charles and George H. Knollenberg. At the time the company had 4 employees.

In Business

George became the president of the small company with Charles as vice-president. Immediately, Charles and George grew the business. In 1892, the business moved to a new building at North 15th St. near the Pennsylvania Railroad.

With a larger facility, the company was able to accommodate a larger staff. They began establishing agencies in major cities coast to coast. Then the Panic of 1893, an economic depression, hit in February. In May, a major company went bankrupt and the Dow Jones dropped 24% in one day.

Still, Charles and George’s company pressed on. But, by the end of September, they didn’t have steady work. Orders were few and those that they were getting were small. After a few weeks, they were half-time. By mid-December they were working 12 men 9 hours a day for 1/3 of the days; whereas, full time was 16 men. They shut down on December 23 and were unsure when they would reopen.

Fortunately, the depression was short lived and the company was able to continue in business.

The First Patent

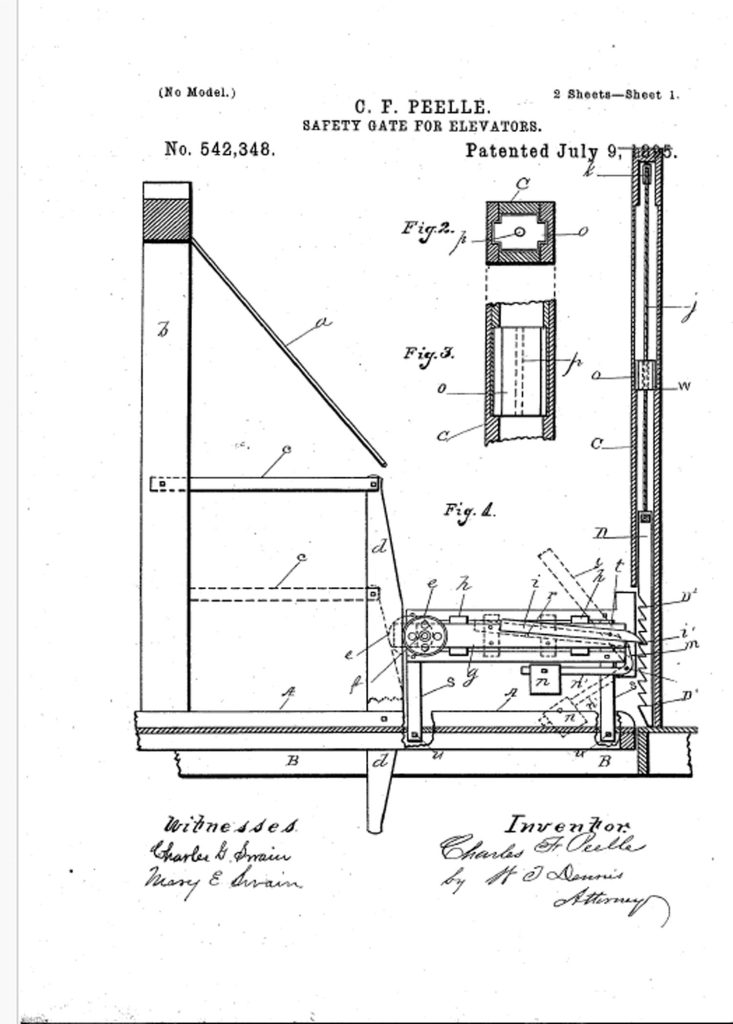

Charles was busy at work with ideas for improvements to the safety gates. On October 17, 1894, Charles filed a patent with the U.S. Patent Office for his invention that provided a

“means by which a safety-gate may be held rigidly in a raised position while the elevator is flush with the floor and is made to descend automatically by the elevator-platform ascending or descending from its position, the elevator platform being permitted to ascend through the successive floors without disturbing the safety-gates in their positions closing the said openings in the floors.” (Source: Patent 542,348, July 9, 1895)

His design included a pulley, a wheel, a tooth bar and more.

In July 1895, Charles was granted patent 542,348 for his invention. To view the patent, enter 0542348 in the patent search field on the Patent Public Search page of the United States Patent and Trademark Office.

The patent and the process show me two things: 1) Patents in the late 1800s were just as confusing as patents today. 2) The patent process took a lot less time in the 1800s than it has in recent years. None of Rod or my patents went through in such a short interval.

Incorporation

Three years later, the company added fire doors to their product offerings. And, in April 1899, Charles and George incorporated their business as Richmond Safety Gate Company with capital stock of $40,000. At the same time that they incorporated their safety gate business, they also incorporated Eureka Fence Manufacturing Company with capital stock of $10,000 with a share price of $100.

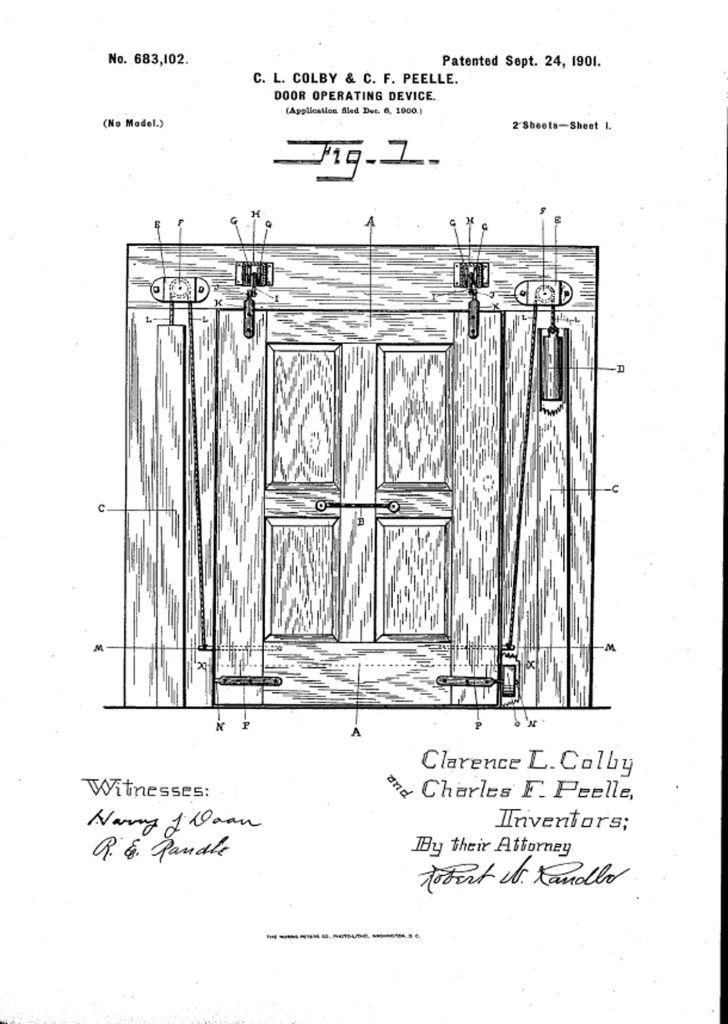

At the end of the next year, Charles filed another invention with the U.S. Patent Office. With Clarence L. Colby, he had invented a door operating device for “doors adapted to be raised and lowered by counterbalancing-weights and to be entirely out of the way when not in use.” Their invention included “a novel construction and arrangement by means of which doors might be operated to open and close doors easily and quickly” Pulleys were again involved.

Charles and Clarence were issued patent 683,102 on September 24, 1901. To view the patent, enter 0683102 in the patent search field on the Patent Public Search page of the United States Patent and Trademark Office.

Death Comes Calling

Charles venture with the Richmond Safety Gate Company ended abruptly just over two months later. He died on December 9, 1901. He was only 45.

The newspaper reported that his death was due to pleuro-pneumonia. However, his death certificate states that the pneumonia was only a contributing factor. It states that the primary cause of death was cerebral neurasthenia.

Businessmen were said to be particularly prone to this condition if they were stressed and overworked. It was said that America’s competitive culture led to this disease and it was referred to as “Americanitis.” The sufferers were said to have fatigue, upset stomach, spinal irritation, weakness, dizziness, and more. It is no longer a diagnosis in the United States.

I do not know the symptoms Charles experienced. However, I think a reasonable theory is that he simply died from exhaustion, having put so much energy into business.

The Company Lives On

Although the company had lost their vice-president and manager, they announced that no changes would be made to leadership until the following year. Despite multiple of Charles’ brothers being involved in the company, it was his business partner George who bought Charles’ share in the company. He also took on the manager responsibility, devoting a portion of his time to that role.

The Philadelphia Lawsuit

The following year, the Richmond Safety Gate Company sued the city of Philadelphia. They claimed that they were being discriminated against and not being allowed to do business in the city. They had been selling their safety gates in Philadelphia for eight years when they suddenly couldn’t sell their product anymore.

They alleged conspiracy between individuals in the local government and certain providers of competing products. The city had notified them not to install any more fully automatic safety gates and had informed businesses to not purchase any automatic safety gates in favor of semi-automatic gates.

The claim was that the fully automatic safety gates were less safe. Furthermore, the city said that they would condemn any fully automatic safety gates that they found. Of course, the Richmond Safety Gate product was fully automatic. And, according to the company fully automatic safety gates were safer than semi-automatic gates. Furthermore, they claimed that the defendants willfully conspired to injure or eliminate their business in Philadelphia.

The lawsuit simply asked for two things. They wanted the defendants to be forbidden from favoring or requiring one type of safety gate over another. And, they wanted the defendants to not be allowed to use their official positions in any way that denied the Richmond Safety Gate Company the ability to freely compete for business in the Philadelphia market.

The judge refused to issue an injunction so the the company could continue business while the case was heard by the court. But, the court did agree to handle it in an expedited manner. So, a year and a half later, the judge handed down his opinion in favor of the Richmond Safety Gate Company.

Ready To Move On

By 1908, George started exploring options for selling the business. He was ready to get out of the manufacturing business. He was nearing retirement and he still had significant other business interests. There was talk of selling the business to C.L. Colby, who previously patented an idea with Charles Peelle. In 1909, it appeared the company ($50,000 capital) would be moving to Marshalltown, Iowa with some of the staff also moving. The deal seemed so close that the company closed down in anticipation of the sale and move. However, the sale fell through at the last minute.

So, George, who had opened his first business in 1866, did what came natural. He opened the factory back up and went back into business. By 1913, the company had expanded to include fire retardant doors and freight elevator enclosures. They now had between 30 and 35 employees on the payroll.

The Union

With World War I, came a demand for workers, which translated into higher wages. At the end of July 1918, the employees of the Richmond Safety Gate Company demanded a wage of 40¢ per hour for all workers, skilled and unskilled, effective immediately. The company had already instituted a bonus system and a 2 1/2¢ per hour pay raise. The company stated that they could not pay all employees 40¢ per hour or they would lose money on their current contract with the U.S. government for tin-clad fire-doors.

Thus, around 50 men went on strike the following Monday. Within a few days, they met with the Sheet-Metal Worker’s Union about joining the union. After the decision to join was made, the union convinced the workers to go back to work and provide the company their grievances in a businesslike manner. Then, the union could fight for them.

The issues stated by employees were wages, the current bonus system, and a disagreement over the actual profits of the company. The current wage for employees of the company depended on who you asked. Clearly, management did not want to pay unskilled workers the same as what they paid skilled workers.

The bonus system, which the company offered was believed by the employees (or the union) to be unfair. They offered a 10 percent bonus if an employee was on time and worked 55 hours in a week without any absences. The employees did not feel it was fair as one minute late or one missed hour could cost you your entire bonus. They much preferred an increased wage.

The union took up their cause and there were many union-company clashes that fall. However, the exact agreement reached is undetermined.

The Buyout

Near the end of December, George died. The following May, his widow sold the company to the Peelle Company that was located in New York. That company was owned by Charles F. Peelle’s brother Caleb M. Peelle. Caleb had been working in New York for Richmond Safety Gate Company at the time of his brother Charles’ death.

By 1905, Caleb decided to form his own elevator company, which he simply name Peelle Company. His company, one might say, was a spin-off of the Richmond Safety Gate Company. And, now the child was purchasing the parent!

The decision was to have the Richmond Safety Gate Company as a wholly owned subsidiary and to have it remain in Richmond, Indiana. The only difference would be that one of the Peelle brothers, who had joined Caleb in his business in New York, would relocate to Richmond and run the company.

Doors, Doors, Doors

Doors, Doors, Doors

With new ownership came a push to expand and grow. In 1921, the Richmond Safety Gate Company moved to a new location. A name change followed the next year when they petitioned to change it from Richmond Safety Gate Company to the Richmond Fireproof Door Company.

Over the coming years, the company continued to focus on various types of doors and related fixtures. In 1924, they stated that they were the makers of the “Richmond Standard Automatic Tin Clad Fire Doors and Fixtures.” It was Underwriter Laboratories approved and the company was recognized for their quality and workmanship. They were seen as setting the standard for fireproof doors.

The company came under the leadership of James F. Peelle in 1926 when he was named president and general manager. The following year, the company reported that they were able to manufacture approximately 100 doors per day. The company made various types and styles of doors, including: swinging, sliding, folding, telescoping, and more. They advertised that they had a single order for 242 doors.

The company came under the leadership of James F. Peelle in 1926 when he was named president and general manager. The following year, the company reported that they were able to manufacture approximately 100 doors per day. The company made various types and styles of doors, including: swinging, sliding, folding, telescoping, and more. They advertised that they had a single order for 242 doors.

$50,000 in improvements were made to the factory. They employed approximately 125 people and planned to further expand the staffing.

It was at this time that the company held their first company picnic with an estimated crowd of 200 to 300. Each person got coupons good for hot dogs, ice cream, and other goodies. The day was filled with races, other competitions, and general enjoyment.

Expansion

Then it was back to work as 1928 brought a major expansion. The floor space was expanded by a third by adding a new 140 ft.by 40 ft. addition to their current 260 ft. by 120 ft. building. The new addition was to house the manufacturing of steel door trim for doors in industry called “Roll Steel Combination Buck and Trim Frames.” To go along with their product and image, the new addition was brick with steel window frames.

At the same time, an additional story was added to the office building.

Custom Doors

The company became known through out the country for problem solving and unique solutions to customer problems. They made custom doors for a local company when the elevator shaft only had 4 feet of clearance below the first floor and the customer required a 10 ft. high door to accommodate automobiles and trucks on the elevator. Typical construction would require at least 5 feet of clearance underneath the elevator. The company’s solution was to create special doors where the bottom section of the door was two parts with one “telescoping” behind the other.

A challenging problem arose when the U.S. government asked for them to create doors for a military installation where the doors had to continue to operate smoothly at -100 degrees. They were created on a tight timeline with complications even in the shipping. However, creative solutions prevailed and the doors arrived at their destination on schedule.

Challenges also came in the way of size. The Power Authority of New York, for example, required two doors for their power plant on the Niagara River that measured 76 ft. by 80 ft. Each door weighed 54 tons. I have no idea how they transported them from Richmond, Indiana to upstate New York.

Motorstairs

Meanwhile, in Coffeyville, Kansas, a small company named Multiscope was born. Incorporated in 1941, Multiscope focused on military projects during World War II.

They had secret gun directors for Navy ships. It was a highly secretive project with 20 to 30 sub-contractors making components, which were assembled at Multiscope. Even the head of the companies didn’t see the finished product. In the third year of production, some of the employees were allowed to see the final product minus several secret components that were removed for the showing.

After the war, the factory was converted for civilian product development. Their first post-war product was moving stairs. Now, I have no idea how or why they chose this for their product. I would assume that somehow escalators were a good match for the type of equipment that they had.

Purchase By the Peelle Company

The Peelle Company became an Eastern sales representative for Multiscope. Then, in 1949, the Peelle Company bought Multiscope, naming the new subsidiary Peelle Motor Stairs, Inc. Their plan from the onset was to move the company to their facility in Richmond, Indiana.

To facilitate the move, they built a new 30,000 sq. ft. building and a new office building on the same site as the Richmond Fireproof Door Company. Co-location was critical as the president of Richmond Fireproof Door Company was also the executive vice-president of Peelle Motor Stairs, Inc. Likewise, others held positions in both companies or moved from one to the other.

Big Contracts

Almost immediately, after the purchase, the company landed a contract for $650,000 to build escalators for the new Union Bus Terminal in New York City. It required a significant increase in staff over the number that had been working in Coffeyville. To ensure a good transition, they moved about 25 previous Multiscope employees and their families from to Richmond while also hiring additional staff.

Although I referred to the product as an escalator, it is said that the term “escalator” was never used at the company. The term had been trademarked by Peelle’s competitor Otis Elevator Company. And, although they had dropped the trademark and it was in the public domain, the Peelle companies did not see fit to use the term.

In 1960, the company got another contract for the Union Bus Terminal, when it expanded. Eighteen of the original thirty one escalators were removed and twenty-eight new escalators were installed. The longest of the escalators was 79 ft. and had 150 steps. They estimated that in the 10 years that the escalators had been in place that they had carried the equivalent of two times the entire population of the United States. So, it is no wonder that some of them needed to be updated.

They installed motorstairs with heated handrails to warm hands in the winter. Oddly that wasn’t in Alaska, where they installed what they believed to be the first ever escalators in Alaska. They carried shoppers at the Northern Lights Shopping Mall in Anchorage.

In 1965, Peelle, exited the escalator business when they sold their escalator company to Haughton.

The Closure

The Richmond Fireproof Door Company manufacturing offices closed in October 1983. They along with their predecessor company, Richmond Safety Gate Company, had been in business there for nearly 100 years. At the time, they were down to 25 manufacturing employees at the Richmond location. The remainder of the manufacturing for the Peelle Company taking place at their plant in Ontario, Canada.

The employees were given 30-day notice that the plant was closing. The following August, they auctioned off all of the remaining equipment.

Spanning Parts of 3 Centuries

The family’s venture into elevators and manufacturing, however, continues. The Peelle Company, which is now 120 years old, has offices in New York and Ontario, Canada with installations worldwide. The company is still owned and operated by the family. JT Peelle, is the current president and CEO of the company and a member of the 5th generation of Peelle family members to serve in the company.

According to the Peelle Company website, “Peelle [is] known for premium quality design and manufacturing of specialist lift and elevator entrance doors. Not only are we known for build quality, more importantly, we are known by all of our customers for product longevity. This results in Peelle being the industry leader in the markets we serve, and the biggest provider of Horizontal and Vertical Sliding Doors for demanding commercial / industrial applications world wide.”

The Peelle Company believes their advantage comes from “continuing to install freight elevator doors on a worldwide basis. This gives Peelle an in-depth and first-hand understanding of what the building owner/manager values in freight elevator door equipment and what is important from an elevator contractor’s perspective.”

They go on to say, “Being family-owned and operated since 1905 has allowed Peelle’s founding traditions and core values to continue on today.”

Genealogical Connection

Company material says that the company is a 5-generation company. My assumption is that it has been led by men in five generations.

Based on this assumption and the fact that Caleb and Charles were my great-grandfather’s 4th cousins. That would make JT my 7th cousin once removed. I am still researching to verify this relationship.

We are much closer connections on LinkedIn as he is a 3rd level connection to me. And, in an interesting coincidence, both JT Peelle and my sons studied at the University of Denver (DU). Both JT Peelle and my oldest son got their MBA at DU.

Mystery Girl

The photograph shown was taken in New York. The photo was among photos that we inherited and which appear to be tied to the Peelle family. Who is she? Is she a descendant of one of the brothers in this Peelle family? If so, why did my family have the photo?

Related Links and Publications

The Richmond Fireproof Door Company

Richmond by The Richmond Fireproof Door Co., 1960.

Richmond Pass Windows by The Richmond Fireproof Door Co., 1960

Richmond Fyrgard Products by Richmond Fireproof Door Co., 1940.

Richmond Fireproof Door Company by The Richmond Fireproof Door Co, 1939.

Richmond doors, frames, hardware, operators by Richmond Fireproof Door Co., 1938

The Peelle Company

Interview With JT Peelle, Current President and CEO of the Peelle Company

Supplier Spotlight: Peelle Turns 100 by Elevator World

Peelle Hanger Doors by The Peelle Company, 1960.

Peelle Doors: freight elevator, dumbwaiter, industrial entrance doors by The Peelle Company, 1936

Peelle freight elevator, dumbwaiter, industrial entrance doors by The Peelle Co, 1932.

Prompt: Wheels

@52ancestors52weeks

Who was Charles?

Who was Charles? Doors, Doors, Doors

Doors, Doors, Doors